Address:

RM. 1103, Lihe Building, NO.59 Suli Road, Suzhou, Jiangsu, China

Tel:

13862166059

Email:

sales@licornechina.com

|

Mill carbon dioxide fire extinguishing system

1. Overview of fire hazard characteristics

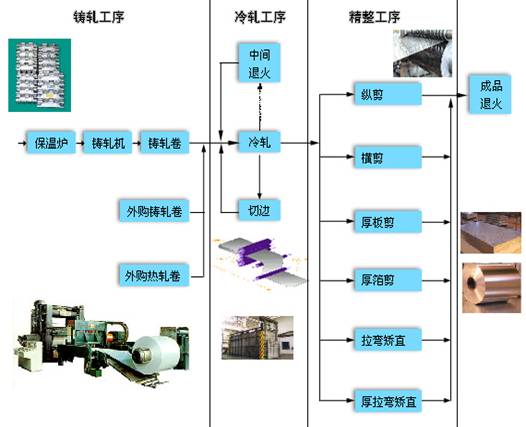

The objects of fire danger in the protective area of the rolling mill are: the process oil in the underground oil storage area and the rolling mill production line in the rolling mill area. If a fire should occur, it should be dominated by a Class B fire. There are also a large number of other flammable solid materials in the rolling mill, and Class A fires should also be considered. .

Due to the high speed operation of the mill rollers, if the lubrication is not in place and the temperature of the individual parts of the mill is high, the oil and gas will suddenly start to catch fire after contact with it. There may be many kinds of ignition sources, such as sparks produced by poor quality electrical equipment, and non-standard operation. Scattered welding slag, lax cigarettes, poor pipe management and grounding. If you do not save or do not save properly, it may result in a very vicious fire.

Lubrication and process oils used in the production process are stored and transported through storage containers, pumps, and pipes. Despite the high flash point of the oil, once it is ignited, the resulting fire is shocking. During the operation of the high pressure oil pump, if there is leakage in the pump, pipeline, container or other parts, especially when the leakage is high, when the leakage is large, the fire will ignite quickly; in addition, some steeling areas are used for weighing. And the work surface, the gap between the steel plate processing are not good enough, sometimes directly from the surface of the fire fall off the middle of the fuel tank, the danger is extremely difficult to express.

Regarding the use of fire extinguishing agents in the end, the author believes that the choice of carbon dioxide is the most ideal and there is no need to think too much about it. First: The partial extinguishment of CO2 fire extinguishing agents cannot be replaced by other fire extinguishing agents. The detailed technology is shown in the table below. Secondly, as far as the current domestic and overseas application of thimble fire fighting applications, there are many practical examples of successful CO2 extinguishing. It is also very successful. Thirdly, the frequency of firing in the twisting machine industry is high relative to other industries. From the economic point of view, this method is also the most economical, and the operating cost is also the lowest.

2, fire extinguishing system

2.1 Fire extinguishing system form selection

Full flooded fire extinguishing method:

The oil depots and grounds of the oil depots are permanently underground, where large quantities of oil are stored. The oil depots are often located in enclosed structures. Therefore, it would be more practical to use full-submerged fire extinguishing methods when designing. However, the maintenance structure of these areas must accompany the basic requirements of an all-submerged fire suppression system:

1) The protected area must be an independent area;

2) The protective structure of the protection zone fire resistance> 0.5h, compressive strength> 1200pa;

3) The closed area shall be kept closed during fire extinguishing. The openings other than the pressure relief port and the fan used in the protection zone shall be

Fire dampers in ventilation ducts, etc. shall be automatically closed before spraying;

4) If the protection zone and the outside world use partitioned glass, in order to achieve the fire protection requirements, fireproof glass shall be used, and the fire resistance limit shall be > 0.5 hours;

5) Before spraying carbon dioxide, it is necessary to cut off the source of flammable gas and combustion gas, and stop all equipments that affect the fire extinguishing effect;

6) The door of the protected area must use a fire door that opens outside and can be automatically closed;

7) The pressure relief port of the protection zone should be located on the external wall and should be located at 2/3 of the net height of the protection zone.

Pressure relief area calculation

F 0.15Q/ P (3.0.6)

Where Fx --- Pressure relief area m2

Qx --- Average discharge rate of heptafluoropropane in the protection zone kg/s

Pf --- Permissible pressure of inner envelope subjected to internal pressure Pa

8) The air flow around the protected object should not exceed 3m/s. When necessary, wind protection measures should be taken.

9) There should be no obstructions within the nozzle spray angle range between the spray head and the protected object.

10) When the object of protection is a flammable liquid, the distance from the liquid surface to the container mouth must not be less than 150mm.

11) When the combined distribution system protects 5 or more protected areas or protective objects, carbon dioxide should have a reserve, and the reserve should not be less than the system designed storage. Reserve volume storage containers should be connected to the system pipe network, and should be able to switch with the main storage container.

The above requirements should be strictly observed and truly implemented. Otherwise, the entire system can only stay in the stage of performance when it is accepted.

Local application of fire extinguishing methods:

Hosts, plate filters, and stick seams are all exposed and cannot form closed spaces. Therefore, it is ideal to use partial fire suppression when designing. However, for nozzles in local application systems, hooded nozzles are used. The protection area formed by the spraying hoods must be determined experimentally. The nozzle installation height, inlet pressure, installation angle, and surrounding wind speed all play a decisive role in the fire extinguishing effect. Although most designs have a large number of dose calculations, it does not mean that they can effectively extinguish the fire. Therefore, the design of local fire extinguishing systems must be cautious. It is necessary to consider the residence time of gas shields formed on the surface of irregular bodies after carbon dioxide injection. And shape.

2.2 Number of fire extinguishing

See "Table 1". Without considering the simultaneous fire between the two fire zones (according to our specifications), the machine fire extinguishing system generally requires that the machine body be capable of two fire extinguishing. At this time, the amount of medicines stored in the system can also be realized. Plate filter twice fire extinguishing and four extinguishing capabilities of the oil depot. In addition, when the main part of the rolling mill extinguishes fire, it is necessary to drive the flue to extinguish the fire; The flue is a separate set of main and standby sets of bottles, sticks and sumps are also separate sets of main and standby sets of bottles, because they can be used alone, it does not appear in the "Table One." In actual engineering projects, owners often consciously or unintentionally raise fires in two districts at the same time and require that they be resolved. For this reason, the system should set the fire extinguishing dose according to “Table 1” when storing medicaments, but the method of starting the system is slightly different from the former, but it can be achieved completely.

"Table I"

Twisting machine fire extinguishes twice

Filter twice at a time

Technical Lubricant Library Once Two Times Three Times Four Times

Thin oil reservoir once two times three times four times

In the process of engineering design, we can look at the economic conditions of Party A. We can propose to set up the system in accordance with “Table 2”. This will not only satisfy the current regulations in China, but also can simultaneously extinguish the entire production line and enable the machine to fire and filter three times. Three fire extinguishers, three extinguishments in the oil depot, and the goal of extinguishing the fire in any combination of two.

"Table II"

Twist machine fire extinguishes once twice three times

Filter once twice three times

Technical Lubricant Library once two times three times

The entire fire zone

3. Fire detection and alarm system

3.1 Selection of fire detection types

Protection Area Probe Type Selection Reason

Machine body flame detector, point difference fixed temperature detector or fixed temperature tubular detector In fact, in the twisting machine using flame detector is the fastest way to detect, but often let other external UV source interference, the system is old Inadvertent alarms, so users do not welcome such methods. This situation can be achieved only by taking some simple measures in terms of detection angles. The installation of differential temperature detectors should not stick to the rules, and the detectors should be arranged as close as possible to the fire point according to the shape of the machine, without affecting the normal operation, in order to eliminate the weakening of the performance of the air flow.

Stick seam Flame detectors (double- AND gates) have a high probability of catching fire. Attention must be paid to the installation of detector beam range control grids when using flame detectors.

Flue air tube temperature detector or recoverable cable temperature detector

Oil sump Point-type constant-temperature and differential-fixed-temperature detectors Air flow has little effect on its temperature range, and it is practical to use point-type detectors.

Main Tunnel Point-type constant-temperature and differential-fixed-temperature detectors The use of point-type detectors in the interior of a closed space is ideal, and it has proved practically practical.

Oil depot Point-type constant-temperature and differential-fixed-temperature detectors The use of point-type detectors in the interior of a closed space is ideal, and it has proved practically practical.

Filter Flame detector, point difference fixed temperature detector or fixed temperature tubular temperature detector

3.2 Alarm Settings

Sound and light alarm devices shall be set inside and outside the oil depot and main tunnel protection area. To ensure the safe evacuation of personnel, a fire alarm shall be issued before releasing the fire extinguishing agent. The delay time from fire alarm to release of fire extinguishing agent shall be in accordance with the actual Set after the situation test, can not be deliberately set 30S; do not delay the machine body, flue, filter, stick joints, spray immediately when the conditions are met; when the plate filter alarm, underground oil tanks to alarm at the same time; host During the alarm, the underground oil depot and the main trench shall alarm at the same time; in order to ensure the reliability of the fire extinguishing, the necessary linkage operation shall be ensured before or at the same time when the fire extinguishing system releases the extinguishing agent, that is, when the fire extinguishing system issues a fire extinguishing instruction, the control system sends the linkage Instructions, cut off the power supply, shut down or stop all equipments that affect the fire extinguishing effect. In the actual operation, since the system detection uses the “AND gate” circuit, all areas should be in an automatic state, and should not put any area in manual operation. In the control state, because the manual control in the automatic state is a priority, because the probability of accidental spraying in this control mode is really Normally low; the main console, entrance console, and exit console are all equipped with operation buttons of the main unit (main and backup areas); three buttons are arranged near the main console to serve as roll gaps and hosts (main and spare areas) The start and stop buttons of the rest of the districts are divided into two modes: the main body and the main operation room control, but the buttons of the main operation room should be placed separately from the buttons of the roll gap (main and backup areas); host, underground oil depot, main trench, Manual fire stop button facilities are installed in fire-fighting areas such as panel filters.