Address:

RM. 1103, Lihe Building, NO.59 Suli Road, Suzhou, Jiangsu, China

Tel:

13862166059

Email:

sales@licornechina.com

|

Mechanical stereo parking garage carbon dioxide gas fire extinguishing system

A mechanical and stereoscopic garage is a garage for parking a car in a form of vertical or horizontal movement without mechanical lanes and no personnel staying in the room.

1. The definition of fire protection category for mechanical parking garage:

At the beginning of the design of a closed vertical garage, the fire protection category of the garage must be first identified. The fire protection classification of the garage should be divided into four categories and should comply with the following table.

Garage fire classification table

Category Quantity Name I II III IV

Car Bank >300 Vehicles 151~300 Vehicles 51~150 Vehicles ≤50 Vehicles

Repair garage >15 parking spaces 6~15 parking spaces 3~5 parking spaces ≤2 parking spaces

Parking lot >400 vehicles 251~400 101~250 vehicles ≤100 vehicles

The mechanical parking garage should belong to the category of garages. According to the current garage size on the market, it basically belongs to category IV and III garages. The fireproof rating of the garage should be divided into three levels. The fire performance and fire resistance of the fire-rated building components at all levels should not be lower than the table below.

Fire resistance performance and fire resistance limit table of fire-rated building components at all levels

Combustion performance and fire resistance (h)

Component Name Fire Rating

Level 1 Level 2 Level 3

Wall Firewall Not Burning Body 3.00 Not Burning Body 3.00 Not Burning Body 3.00

Load-bearing walls, stairwell walls, fireproof partitions Non-burning bodies 2.00 Non-burning bodies 2.00 Non-burning bodies 2.00

Partition wall and frame infill wall Non-burning body 0.75 Non-burning body 0.50 Non-burning body 0.50

Columns Supporting multiple layers of columns Non-burning bodies 3.00 Non-burning bodies 2.50 Non-burning bodies 2.50

Column supporting single layer Not burning body 2.50 Not burning body 2.00 Not burning body 2.00

Beam Not Burning Body 2.00 Not Burning Body 1.50 Not Burning Body 1.00

Floor Not Burning Body 1.50 Not Burning Body 1.00 Not Burning Body 0.50

Evacuation stairs, ramps Non-burning bodies 1.50 Non-burning bodies 1.00 Non-burning bodies 1.00

Roof load-bearing components Non-combustion body 1.50 Non-combustion body 0.50

Pendant (including ceiling joists) Non-combustion 0.25 Non-combustion 0.25 Refractory 0.15

The fire resistance rating of Class III garages should not be lower than Grade II; the fire resistance rating of Class IV garages should not fall below Class III.

Although the "Fire Protection Code for Design of Garages, Garages, and Parking Garages" GB 50067-97 has set specific requirements for the fire resistance rating of Type IV and III garages, if the fire extinguishing system uses a carbon dioxide gas fire extinguishing system, the doors and windows of the garage should not be The protective structure should also meet the specific requirements set out in the “Code for Design of Carbon Dioxide Gas Fire Extinguishing Systems”, namely:

(1) For gases, liquids, electrical fires and solid surface fires, openings that cannot be automatically closed prior to the release of carbon dioxide shall not have an area greater than 3% of the total internal surface area of the protected area, and openings shall not be provided on the floor.

(2) The fire-resistance limit of the envelope structure and the doors and windows of the protection area shall not be less than 0.50h; the allowable pressure of the envelope structure and doors and windows shall not be less than 1200Pa.

(3) The storage device should be set up in a dedicated storage container. The storage container should meet the following requirements:

Should be close to the protection zone, the exit should lead directly to the outdoors or evacuation walkway; fire resistance level should not be lower than 1.50h; indoor temperature should be 0 ~ 49 °C, and should be kept dry and well ventilated; should be located in the underground storage container Mechanical exhaust device, exhaust outlet should lead to the outside.

2. Some matters that should be noted when designing a high-pressure carbon dioxide gas fire extinguishing system:

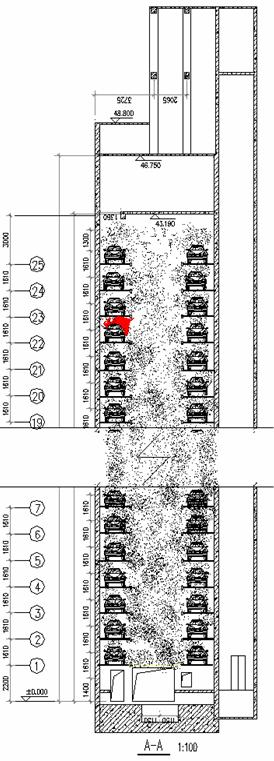

2.1 Stereo Parking Garage Installation The CO2 gas fire extinguishing system has been stipulated in the "Fighting Code for Design of Fire Protection for Automobile Storage Garage, Garage and Parking Lot". Since the parking garage is an independent large space, the use of flooded units in an independent manner is the most important. Ideally, there are two reasons for setting the high pressure system without setting the low pressure system: First, the pressure of the low pressure system is too small, and it is necessary to climb to a height of more than 40 meters and then discharge the chemicals. The apparent pressure is insufficient; second, the large tank of the low pressure system only Can be placed on the first floor or the second floor, which is conducive to the future addition of pharmaceuticals, if the storage tank to ensure that the pressure is too high, the CO2 tank car simply can not be close, filling the drug is difficult to achieve.

If the garage is small and the pressure of the low-pressure CO2 fire extinguishing system can be satisfied, the low-pressure system can also be set.

For open-air three-dimensional garages, it is best to use local protection fire extinguishing methods. At this time, because the height of the garage is generally not high, the CO2 fire extinguishing system may use high-pressure or low-pressure systems as the case may be.

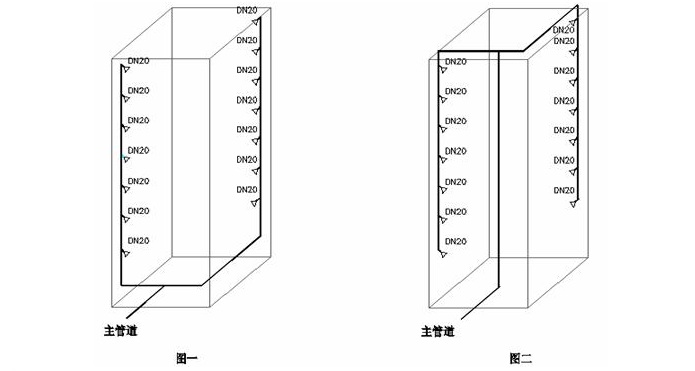

2.2 In the design of a closed vertical three-dimensional garage, the design of the main pipeline should adopt the method of Figure 1, but most of the design institutes adopt the method of Figure 2.

Although the method of Figure 2 minimizes the differential pressure in the elevation, the pipeline loss is nearly half that of the map. After several calculations, the method in Figure 2 is obviously worse than that in Figure 1, and the large-diameter pipeline used is A lot bigger than the map, neither the economic pressure effect is good, the construction volume and difficulty are also much larger.

After the calculation, the pressure is really not enough, and it should be treated in specific situations. It is necessary to leave a dedicated room for the structure when the cylinder room is set near the top; when the garage is high, the method of centrally placing steel cylinders into pipes can also be considered. In short, when designing a three-dimensional garage carbon dioxide fire extinguishing system, it is necessary to repeatedly check the pressure and adjust the system setting method.

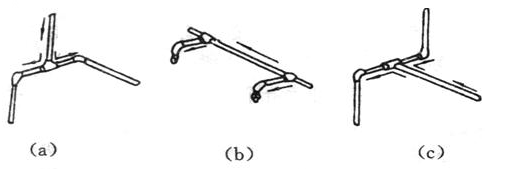

In addition, the three links on pipelines are almost all installed in the “vertical direction”. This is in line with the “3.6.4 halon 1301 fire extinguishing system and the three-way pipe joint of the carbon dioxide fire extinguishing system” in the “Code for the Construction and Acceptance of Gas Fire Extinguishing Systems”. Horizontal installation." A great deal is violated. The specification has mentioned the "ought" explanation: a term that is strict and should be done under normal circumstances. The installation space of the pipeline inside the three-dimensional parking garage is indeed very small, but it is an abnormal situation. However, the quantity is too much and the depth of influence is large. The correctness of the pressure value calculated according to the formula remains to be examined.

It is recommended to use the following installation method as close as possible to the specification.

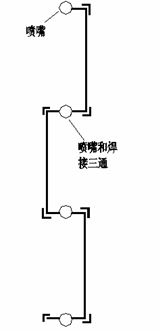

2.3 For the calculation of pressure, the nozzle area of each nozzle must be calculated in detail and strictly used as the basis for ordering. Because the nozzle area of this nozzle is related to whether the entire system can divide the agent according to the number of nozzles. As shown in Figure 1, because carbon dioxide is heavier than air, it will rapidly sink to the bottom of the garage. Once the specifications of the nozzle are not set according to the design regulations, the chemical sprayed unevenly, causing the concentration of fire extinguishing agent on the garage to be insufficient, and the following concentration is too high. Occurs and severely affects the fire extinguishing effect or directly leads to failure of fire extinguishing. As shown in Figure 2, the system should be as uniform as possible during the specified period of spraying, so that the true role of physical CO2 extinguishing can really be achieved.

3, fire automatic alarm system should pay attention to several matters in the design:

There are many reasons for cars catching fire, but they are accompanied by a lot of smoke and flames, because the materials used in automobile manufacturing are very complicated, and wood, plastics, fibers, silk, fur, etc. are all available. When we do fire detection, the selection and installation position of fire detectors is very important. Many of the construction projects in use currently employ a point-type temperature sensation in the front part, a point-type smoke sensation in the rear part, or a cross arrangement. It does not take into account the front of the car to distinguish. However, after analyzing the reaction of the fire detection system after a car fire, we will make a final conclusion.

If the car engine fire, smoke and hot air will rise up from the hollow with the ventilation system of the stereo garage. Obviously, only the front detector will alarm first, and the detector at the rear end will wait for a while to report the fire. The time difference should not be ignored. When there is a fire in the rear of the car, there is only one type of detector alarm. In order to comprehensively construct the project cost and performance, we propose that the front of the car should be equipped with smoke and temperature, and a smoke and temperature should be arranged at the rear of the car to accelerate the reaction speed of the fire detection system.

However, installing smoke and temperature composite detectors in this environment is not very suitable. The reason is that after the fire, the detector must have enough smoke and temperature to alarm, and the temperature radiation can trigger the spot-type temperature sensing, but when there is not enough smoke, the detector It does not move, so there will be time differences.

If economic conditions permit, it is recommended to use an air-suction smoke detector so that the fire can be detected as soon as possible. The garage manager can detect the fire in time and start the fire-extinguishing system manually. The front of the vehicle is equipped with a point temperature. The detector is also necessary, one is for fire protection acceptance, and the other is that the system automatically starts the fire extinguishing system when no one is on duty.

Stereoscopic garage fire detection actually requires the industry to constantly summarize and explore. The above opinions cannot be perfected, but can only be reluctant to adapt, because the three-dimensional garage is like a chimney, with bottom-up self-priming, and the detector The installation location is severely restricted by the structure of the garage, and the proper capabilities of the detector cannot be fully realized.